In the ever-evolving landscape of technology, the fusion of 3D printing and control panel customization has ushered in a new era of immersive experiences. This marriage of cutting-edge technologies not only enhances user interfaces but also opens doors to a realm of possibilities. Join us as we delve into the intricacies of this transformative synergy.

Unveiling the Power of 3D Printing

3D printing, once a futuristic concept, has now become a cornerstone of innovation. Its ability to materialize digital designs into tangible objects has revolutionized various industries. From prototyping to manufacturing, 3D printing has emerged as a game-changer, allowing for unprecedented levels of customization.

Precision in Control: Tailoring Interfaces for Seamless Interaction

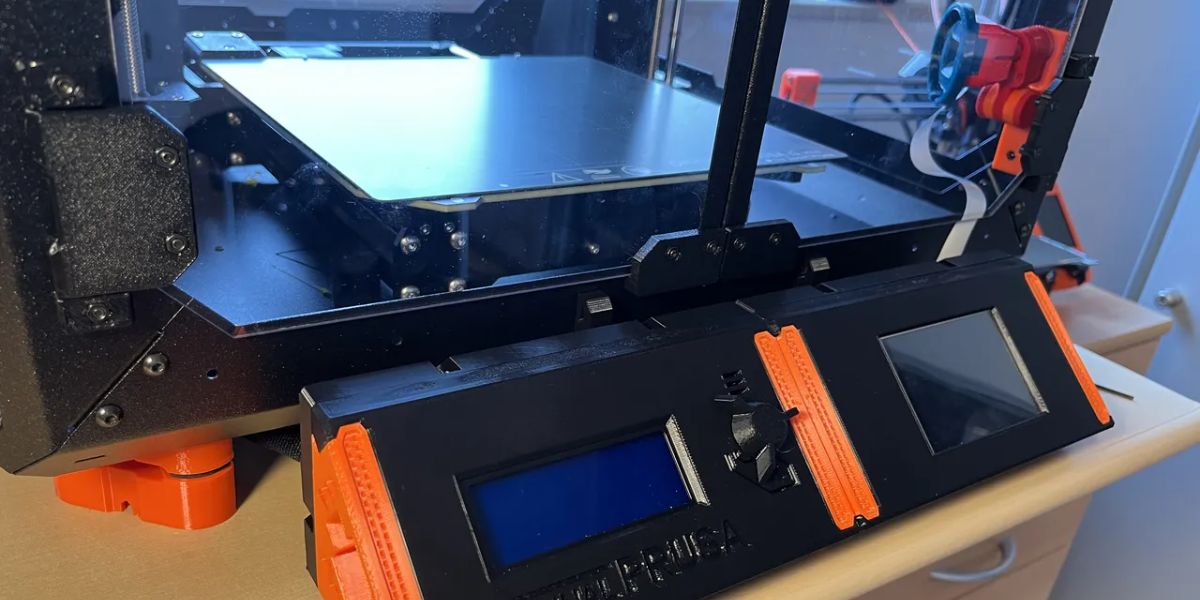

Control panels serve as the gateway to numerous electronic devices, and customization plays a pivotal role in optimizing user experience. Leveraging 3D printing, manufacturers can now tailor control panels with precision, ensuring an ergonomic design that aligns seamlessly with user needs. The marriage of these technologies results in interfaces that are not just functional but also aesthetically pleasing.

The Symbiosis: Enhancing Aesthetics and Functionality

The synergy of 3D printing and control panel customization goes beyond mere functionality. It brings forth a harmonious blend of aesthetics and practicality. Intricate designs and user-centric layouts can be crafted, offering a visual feast while ensuring optimal functionality. This integration caters to the growing demand for products that marry form and function seamlessly.

Realizing Cost-Efficiency: A Boon for Industries

Incorporating 3D printing in control panel customization not only enhances the design process but also proves to be cost-effective for industries. The ability to create prototypes swiftly and iterate designs without significant expenses revolutionizes the product development cycle. This cost-efficiency trickles down to consumers, making cutting-edge technology more accessible.

Ensuring Compatibility: A Technological Symbiosis

Harmony between hardware and software is crucial for any technology to thrive. The marriage of 3D printing and control panel customization ensures compatibility on multiple fronts. Whether integrating with existing systems or paving the way for future advancements, this technological symbiosis creates a foundation for seamless connectivity.

Unraveling the Future: 3D Printing in Consumer Electronics

As 3D printing continues to evolve, its impact on consumer electronics is becoming increasingly pronounced. From personalized remote controls to bespoke dashboard interfaces in cars, the future holds endless possibilities. The immersive experiences facilitated by this synergy will redefine how we interact with everyday devices.

Overcoming Challenges: Fine-Tuning the Process

While the integration of 3D printing and control panel customization presents immense potential, it is not without challenges. Fine-tuning the process to ensure mass production efficiency and maintaining high-quality standards are areas where ongoing research and development are crucial. Addressing these challenges will be paramount for widespread adoption.

The Role of Artificial Intelligence: Shaping the Future

Artificial Intelligence (AI) plays a pivotal role in optimizing the marriage of 3D printing and control panel customization. Machine learning algorithms analyze user interactions, preferences, and feedback to refine designs continually. This iterative process ensures that the technology evolves in tandem with user needs and preferences.

Security Concerns: Safeguarding Immersive Experiences

With increased connectivity comes the need for heightened security. Immersive experiences through 3D printing and control panel customization raise concerns about potential vulnerabilities. Addressing these security issues is imperative to ensure that users can enjoy the benefits of customization without compromising their data or device integrity.

Future Landscape: Bridging the Digital and Physical Realms

The amalgamation of 3D printing and control panel customization signifies a broader trend—the blurring of lines between the digital and physical realms. As we stride into the future, this integration will likely extend beyond consumer electronics, influencing diverse sectors such as healthcare, architecture, and beyond.

Final Words

In conclusion, the marriage of 3D printing and control panel customization marks a paradigm shift in immersive experiences. Beyond the visual appeal, this synergy addresses practical needs, reshaping how we interact with technology. As industries embrace this transformative journey, the future promises a tapestry of seamlessly integrated, customizable experiences.

Commonly Asked Questions

Q1: How does 3D printing impact the cost of control panel customization?

3D printing significantly reduces prototyping costs, making control panel customization more affordable for both manufacturers and consumers.

Q2: Can 3D printing be applied to existing control panels?

Yes, with proper adaptation, 3D printing can be integrated into existing control panels, offering a cost-effective upgrade.

Q3: What role does AI play in optimizing 3D-printed control panels?

AI refines designs based on user interactions, preferences, and feedback, ensuring continuous improvement and customization.

Q4: Are there security measures in place for personalized control panels?

Addressing security concerns is a priority, with ongoing efforts to safeguard user data and device integrity in immersive experiences.

Q5: How does the integration of 3D printing and control panel customization extend beyond consumer electronics?

This integration is poised to influence diverse sectors, from healthcare to architecture, bridging the digital and physical realms in unforeseen ways.

Advertisement